On July 20th 2017, the U.S. National Institute of Food and Agriculture (NIFA), part of the Department of Agriculture (USDA), announced a $4.6 million grant for research on nanotechnology applied to agriculture and food industry. “Nanotechnology is being rapidly implemented in medicine, electronics, energy, and biotechnology, and it has huge potential to enhance the agricultural sector,” said NIFA Director Sonny Ramaswamy. “NIFA research investments can help spur nanotechnology-based improvements to ensure global nutritional security and prosperity in rural communities.” [1]

The applications of nanomaterials and nanotechnology to food industry are large: nutrient encapsulation, food safety, packaging, sensors, nutrients delivery or pathogen detection.

The encapsulation process consist on the entrapment of an active ingredient (food bioactive molecules such as antioxidants, vitamins, essential fatty acids, or even probiotics) inside an enclosing material that can be also proteins, lipids, carbohydrate polymers… For example, prolamin (also called zein), ta protein extracted from corn, has been used as a carrier for flavor compounds and bioactives [2]. β-carotene is a terpenoid abundant in plants and fruits and a precursor of vitamin A. It has been reported that the encapsulation of β-carotene in prolamin fibers obtained by electrospinning technique helped to improve its oxidative and light stability [3].

Also enzymes, which are high specificity molecules with catalyst functions, have been successfully encapsulated. The high cost of the enzymes, their temperature and pH sensibility and the risk of inactivation by agents, have been overcome by development of immobilized enzymes [4]. Enzyme immobilization consists on the confinement of the enzymes within solid matrices [5]. This technique enhanced enzyme stability against pH and temperature changes and also served as a controlled release system.

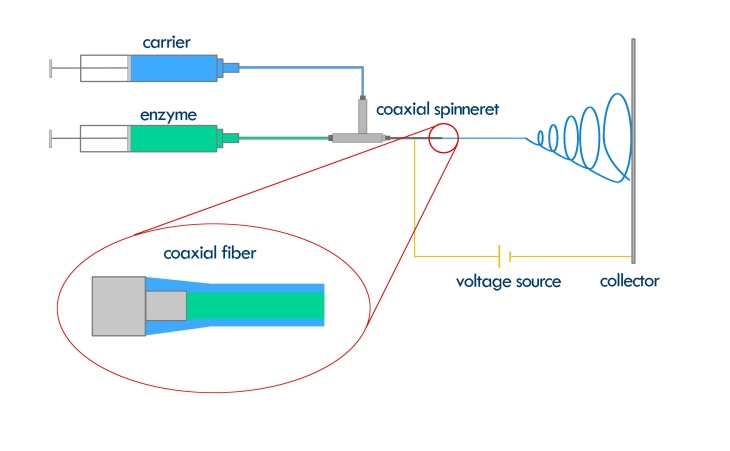

Coaxial electrospinning fibers are excellent enzyme encapsulators, as they entrap the enzymes in a protective coating while the crosslinked resulting fibers increase the porosity and surface area [6]. This facilitates enzymatic reactions and even maintains the enzymatic activity of the immobilized enzyme up to 65% of the activity of the free enzymes [7]. The encapsulation of the enzyme can be done with Nadetech’s ND-ES Lab Electrospinning Unit with a coaxial injection system with two or more different substances, as it is shown in the diagram.

Coaxial fibers formation. Nadetech Innovations

[1] https://nifa.usda.gov/announcement/usda-announces-46-million-nanotechnology-research

[2] Duran, Nelson, and Priscyla D. Marcato. “Nanobiotechnology perspectives. Role of nanotechnology in the food industry: a review.” International Journal of Food Science & Technology 48.6 (2013): 1127-1134.

[3] Fernandez, A., Torres-Giner, S., & Lagaron, J. M. (2009). Novel route to stabilization of bioactive antioxidants by encapsulation in electrospun fibers of zein prolamine. Food Hydrocolloids, 23(5), 1427e1432.

[4] Bhushani, J. Anu, and C. Anandharamakrishnan. “Electrospinning and electrospraying techniques: Potential food based applications.” Trends in food science & technology 38.1 (2014): 21-33.

[5] Brena, B. M., & Batista-Viera, F. (2006). Immobilization of enzymes. In Immobilization of enzymes and cells (pp. 15e30). Humana Press.

[6] Lopez-Rubio, A., Sanchez, E., Sanz, Y., & Lagaron, J. M. (2009). Encapsulation of living bifidobacteria in ultrathin PVOH electrospun fibers. Biomacromolecules, 10(10), 2823e2829.

[7] Wu, L., Yuan, X., & Sheng, J. (2005). Immobilization of cellulase innanofibrous PVA membranes by electrospinning. Journal of Membrane Science, 250(1), 167e173.

© Nadetech Innovations 2017